Professor Lindsay Greer, Professor of Materials Science and Sidney Emeritus Fellow, has been leading a team from the University of Cambridge, who, along with colleagues from the Austrian Academy of Sciences and the Montanuniversität in Leoben, have found a new way to make a possible replacement for rare-earth magnets: tetrataenite, a ‘cosmic magnet’ that takes millions of years to develop naturally in meteorites.

Many of our electronic devices and mechanical components rely on rare earths. That’s especially true for greener technologies – high-performance magnets, which are vital for everything from wind turbines to electric cars, require these elements.

“Rare earth deposits exist elsewhere, but the mining operations are highly disruptive: you have to extract a huge amount of material to get a small volume of rare earths,” said Professor Greer. “Between the environmental impacts, and the heavy reliance on China, there’s been an urgent search for alternative materials that do not require rare earths.”

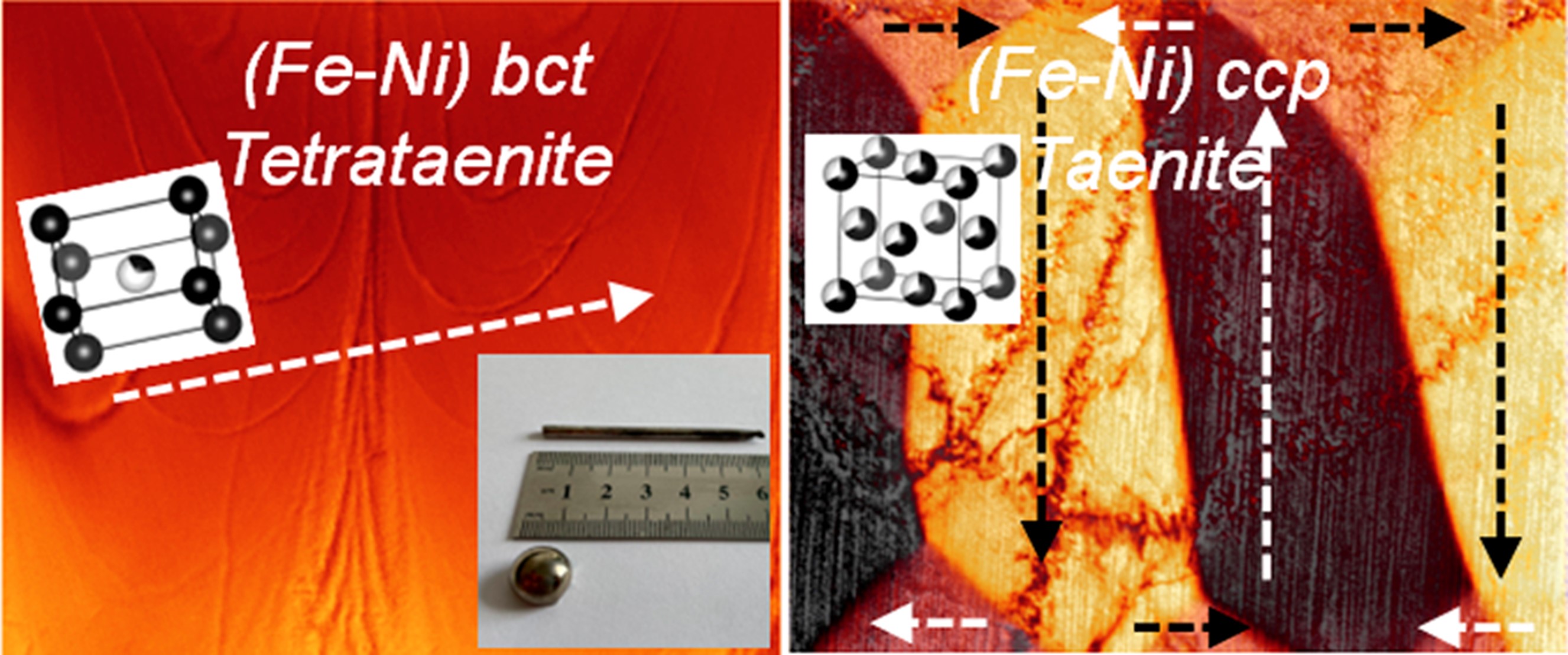

Tetrataenite, an iron-nickel alloy with a particular ordered atomic structure, is one of the most promising of those alternatives, however it’s not easy to come by and is mostly found in meteorite samples where it has taken millions of years to form. As a meteorite slowly cools, tetrataenite forms, giving the iron and nickel atoms enough time to order themselves into a particular stacking sequence within the crystalline structure, ultimately resulting in a material with magnetic properties approaching those of rare-earth magnets. However, previous attempts to make tetrataenite in the laboratory have relied on impractical, extreme methods. But the addition of a common element – phosphorus – could mean that it’s possible to make tetrataenite artificially and at scale, without any specialised treatment or expensive techniques.

“What was so astonishing was that no special treatment was needed: we just melted the alloy, poured it into a mould, and we had tetrataenite,” said Professor Greer. “The previous view in the field was that you couldn’t get tetrataenite unless you did something extreme, because otherwise, you’d have to wait millions of years for it to form. This result represents a total change in how we think about this material.”

High-performance magnets are a vital technology for building a zero-carbon economy, and the best permanent magnets currently available contain rare earth elements. Despite their name, rare earths are plentiful in Earth’s crust. However, China has a near monopoly on global production: in 2017, 81% of rare earths worldwide were sourced from China. Other countries, such as Australia, also mine these elements, but as geopolitical tensions with China increase, there are concerns that rare earth supply could be at risk.

Lindsay tells us "I really did not expect that our team would make such good progress in meeting one of the clearest and longest-standing challenges in the world of permanent-magnet materials."

While the researchers have found a promising method to produce tetrataenite, more work is needed to determine whether it will be suitable for high-performance magnets. The team are hoping to work on this with major magnet manufacturers.

To read the full article on the University’s website please click here.

The results are reported in the journal Advanced Science.

If you have something that would make a good news or feature item, please email news@sid.cam.ac.uk